- info@spark-engg.com

- Muscat, Sultanate of Oman

Gas Analyzers

Gas Analyzers

Spark Engineering & Trading Services offers an advanced range of Gas Analyzers designed for precise gas composition analysis across various applications. Our analyzers are engineered to deliver accurate and reliable data, enabling you to make informed decisions, enhance product quality, and maintain safety standards.

- Oxygen & Hydrogen Analyzers

- Gas Chromatograph

- IR Gas Analyzers

- Electrochemical Analyzer

- Particle Analyzer

- H2S & CO2 Analyzer

Features

- High Precision Measurement: Gas Analyzers are renowned for their ability to provide highly precise measurements of gas composition, ensuring accurate and reliable data critical for process control and quality assurance.

- Real-Time Monitoring and Data: These analyzers offer real-time data collection and monitoring capabilities, enabling immediate insights into gas composition, allowing for informed decision-making, and supporting rapid process adjustments.

- Versatile Gas Compatibility: Gas Analyzers are designed to analyze a wide range of gases, making them versatile for different industries and applications, ensuring flexibility and adaptability.

- Safety Enhancement: Gas Analyzers play a pivotal role in maintaining safe operating conditions, preventing incidents related to gas composition, and improving overall safety in industrial processes, supporting compliance and safety standards.

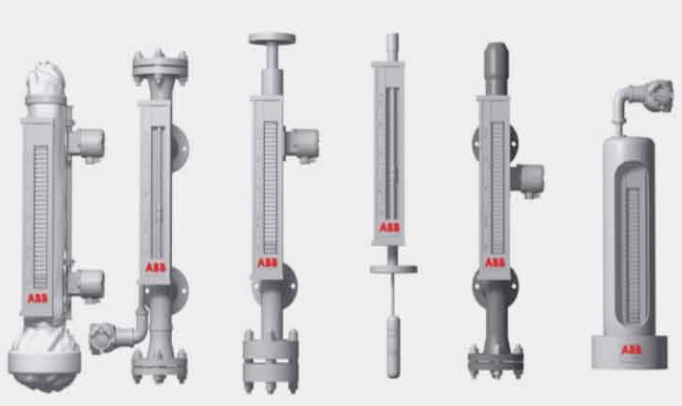

LEVEL GUAGES

Level Gauges, provided by Spark Engineering & Trading Services, are essential instruments designed for accurate level measurements in various applications. These gauges are engineered to ensure precise, reliable, and durable level readings, supporting operational control and safety.

- Accurate Level Measurement: Spark's Level Gauges offer highly accurate and dependable level measurements, crucial for process control and safety.

- Customized Solutions: We provide a range of Level Gauges tailored to your specific application needs, ensuring precise level measurements in diverse industries.

Features

- Precision and Reliability: Our Level Gauges are engineered for high precision and reliability, delivering consistent and trustworthy level data vital for process control and safety

- Customization Options: We offer a variety of Level Gauges to meet your unique requirements, accommodating different tank sizes, fluid types, and environmental conditions.

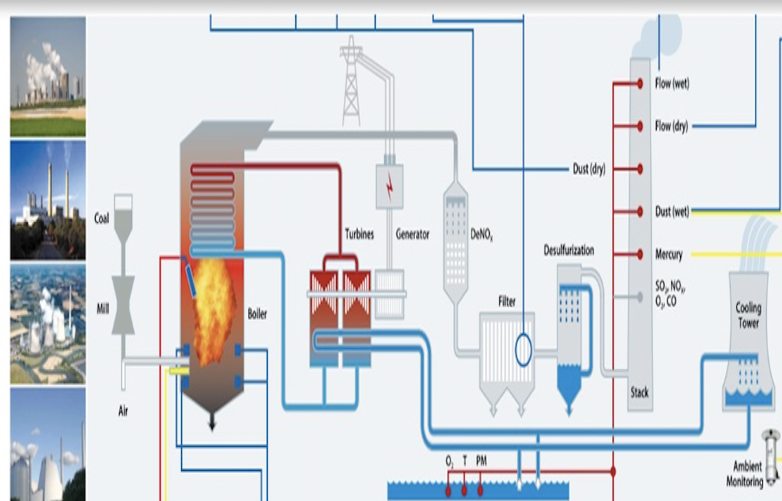

CONTINUOUS EMISSION MONITORING SYSTEMS ( CEMS )

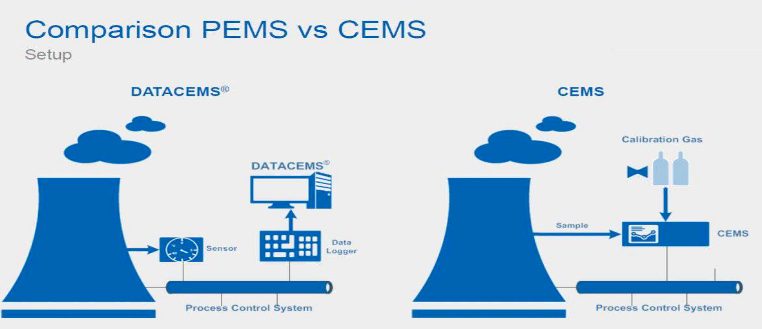

Continuous Emission Monitoring Systems, or CEMS, provided by Spark Engineering & Trading Services, are comprehensive equipment solutions essential for accurately measuring gas or particulate matter concentrations and emission rates. They utilize pollutant analyzers in combination with conversion equations, graphs, or computer programs to deliver results in compliance with the emission limitations and regulations set forth by authorized bodies.

Features

- Compliance Assurance: CEMS provided by Spark Engineering & Trading Services ensure industries' compliance with environmental regulations, delivering accurate measurements essential for meeting emission standards.

- Industry Collaboration: In collaboration with renowned manufacturers, Spark offers state-of-the-art CEMS systems to a wide range of industries, guaranteeing access to cutting-edge technology and expertise for emissions monitoring.

PREDICTIVE EMISSION MONITORING SYSTEMS (PEMS)

Predictive Emission Monitoring Systems, or PEMS, offered by Spark Engineering & Trading Services, are innovative and cost-effective solutions designed to predict gas concentrations or emission rates using process or control device operating parameter measurements. These software-based systems provide real-time monitoring of pollutants and reference variables, such as NOX, SO2, CO, HC, and 02.

- Tailored Predictive Models: Our PEMS solutions are designed to be highly adaptable and offer the flexibility to create predictive models customized to the unique processes and emission sources of your industry. This customization ensures that the PEMS accurately predicts emissions based on the intricacies of your operations, optimizing environmental compliance and emission management. We work closely with you to develop and implement PEMS that align with your specific requirements, offering tailored predictive models for enhanced accuracy and efficiency.

Features

- Significantly lower capital expenditures

- A fraction the operating and maintenance costs of a CEMS

- Maintenance and repair costs virtually eliminated

- Valid results for all operating conditions reflected in the model including startups or shutdowns

- Resilient to missing inputs - sensor failure does not impair data availability

- PEMS can be used as diagnostic tool to lower emission